-

Posts

1,355 -

Joined

-

Last visited

-

Feedback

100%

Content Type

Profiles

Forums

Events

Gallery

Media Demo

Store

Everything posted by GTRPSI

-

Sorry you asked for oil ways, they were done at 8mm for the main bearing feeds, just a normal drill bit from a drill bit set, did not have to be longer than a standard bit. Then chamfer the hole a little to take the sharp corners off. The grooves in the block for the RB26 bearing feeds were done with a steady hand and old bearings as guides with a dremmel with a cutting wheel, reason i didnt machine them out was because of a design/engineering issue with the design of the RB26 type of groove from the factory, i saw a area they could be improved. The factory RB26 design is deepest at the center of the bearing and shallower where the oil feed comes out creating a restrictive point on oil exit into the channel, mine by hand are deepest at the oil feed point and gradually taper thinner as they approch the ends of the bearings. After all that, the mains were line honed to ensure there were no high spots and that everything was straight and true for the crank.

-

Yes just a normal Bosch 240V drill. Drill bit for the oil drains needed to be moved out right to the edge of the drills chuck for the last Cm as it was a little too short, you can see the edge where it was slipping, the drill bit below was my first pass at 8mm, then went up to 10mm which was a longer drill bit, 180mm and longer is what you really need to comfortably get through the block without changing the position of the drill bit to get the last 1cm or so through.

-

4 Wheel Drive Gtr Gearbox Questions

GTRPSI replied to ossie cossie's topic in Suspension, braking, tyres and drivetrain

Ah, but the thrust bearing is a push type.....looks like out of a R32 GTR in that case, an early type, later ones were a pull type clutch. -

4 Wheel Drive Gtr Gearbox Questions

GTRPSI replied to ossie cossie's topic in Suspension, braking, tyres and drivetrain

What exactly did you want to know? Take a picture where the clutch lever comes out and of the thrust bearing, even the pressure plate if you have it. If the slave was mounted behind the clutch lever (towards the rear of the box) its a pull type clutch, if its mounted on the engine side its a earlier push type. -

You need some load to bed in the rings, start light loads, keep the revs to under half of redline at the start, decelerate to pull the metal off the walls after accelerating, gradually building power as you go along progressivly, drop the oil after 10-15 minutes and repeat the load cycles. Dont baby it, dont wring its neck at the start, drive it normally with load on it, its the load that forces the rings against the walls to bed them in, its the decel that pulls the crap off the walls. Also remember that fresh walls are the roughest, the most heat and wear happens in the first few minutes so you dont want too much load for th first few minutes as it will create a lot of heat due to friction.

-

R33 Gt-r - 1996 Black - Victoria

GTRPSI replied to HelloThere's topic in For Sale (Private Whole cars only)

And factor in resizing the rods if reusing them, new bearings, crank regrind if its not twisted, and very likely a cracked oil pump if the pistons and bores are still OK. While there you may as well rebuild the bottom end and clean out everything the oil runs through including the turbo lines. It may be more logical to simply forge the bottom end or just put a known working engine in. It will be a engine out and back in job and as XKLABA said, very common on GTR's, dont let it turn you off the car, simply factor in the costs of the repair against whats it worth to you. -

Mines Baffles, Catch Can Design, Accusumps

GTRPSI replied to Sub Boy32's topic in Engines & Forced Induction

My catch cans have always used rough stainless wool as filling, it helps to seperate the oil from the mist. -

More than a 7-8mm of clearance with Nitto rods and RB30 crank everywhere. Even if it did foul, you could cut holes in those sections to provide 1mm of space between the rods or crank to the tray and take advantage of the crack scraper effect in those areas....id say the machinist is looking for easy work without hassels....(which there are none appart from drilling and tapping 12 holes and threads in the right place)

-

Mines Baffles, Catch Can Design, Accusumps

GTRPSI replied to Sub Boy32's topic in Engines & Forced Induction

40 weight oil, Nitto oil pump and 1.5mm restricer sounds wrong. Id be running a 50 weight if your clearances are large enough with a 1.1mm restrictor, reduces the amount of oil going up, that needs to go back down again. Sump breather fittings and catch can setup is very important, you need to get the blow by out of the sump, without allowing it as best as possible to go up and breath out of the rocker covers as it will take oil with it. -

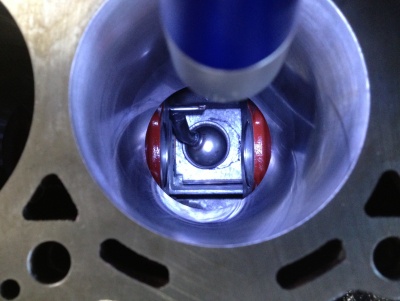

Forgot to add, in the pic below you can actually see the crank girdle with the holes i drilled and tapped to take the RB26 windage trays, yes it does fit, clears the rods and crank and the crank scraper (not pictured) fitted in also, everything clears including the sump. Also if your running a Tomei oil pump there are some extra block mods needed to make it fit, it wont bolt straight on, also the thrust main bearing is modded to provide extra oil to handle the 5700lb pull clutch pressure plate.

-

Ive kept my build private and only shared it with 1 person here to help them out with their 3.2L stroker. Here are some of the oiling mods.... Glyptal paint to aid oil drainback in a deburred block, note the annular grooves like in a RB26 block to provide extra oil and use RB26 race series bearings in a RB30 block. Drilled out all the oil feeds, you can see the tip of the drill bit going into the main feed channel. Drilled out the oil drains to 10mm, this will require opening up the head gasket oil drain points also. There are lots of other little things that can be done to assist oiling and block strength such as Cryo treating the block, partial grout filling etc......

-

Wanted Boot Spoiler

GTRPSI replied to r33-20s's topic in For Sale (Private Car Parts and Accessories)

I have a fibreglass one if you are interested in carbon wrapping it? -

You can cut the lip with the panel painted, its not right up to the edge but near it, even rolled guards are usually not right up to the edge. Any burning of paint on the edge is still from under and can be sealed.

-

The other worry is cracking due to previous hidden repairs. Many GTR's have bog in the rear guards. Our panel beater cut our lips to play it safe. You can seal the cut from under after its been done.