The Wasteland 2011 Edition

Announcements

-

Similar Content

-

Latest Posts

-

By GabsReDeal · Posted

Yes shipping here can be a pain, was about to purchase timing belt replacement kit, but it tends to get expensive due to shipping (and customs if importing from non-EU which the UK now falls under). -

By Murray_Calavera · Posted

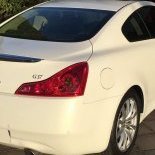

Nah, shouldn't have made any difference. Reds on, or car running, should be same same for what you were doing. -

Should be able to source 200 cell R32 cat... unsure how easy it would be to get it to Malta though.

Recommended Posts