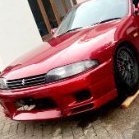

Sending my car in for a 360kw setup next month, need advice.

Announcements

-

Similar Content

-

Latest Posts

-

By joshuaho96 · Posted

Out here E90s are the cheapest way into a sporty-ish car because everyone knows just how expensive the repairs can get. 8-10k USD for an automatic 335i. -

Noted. Have noticed BMW are more 'high maintenance' for sure. They've attracted my attention as I think the used car prices seem reasonable vs other options, and the extra quality overall vs a commodore / camry / corolla or similar of the same vintage is appealing, especially the interior, and they are more on the sporty side whereas the others mentioned can be more cruising or economical A-to-B only.

-

Haha yeah I know, this is SAU after all, why are we talking about BMW's of all things!? I hear you on the 'don't have to worry about it' side of things. Having been fortunate enough to be have been able to buy a brand new motorbike or two...never really enjoyed them as much as I'd have liked as you worry so much about where you park it, will it get scratched, stolen, attempted theft, knocked over, etc...and yes dirty. Older less valuable bikes you can just go where you want and park it wherever and not really worry that much in comparison. And who cares if it gets dirty! Never owned a V8, and have had my eyes on VE / VF commodores for years but with their prices climbing so high, the M3 has come into focus more as prices are much closer than I've ever seen...is it a potential contender now?...of course need to factor in the S65 'maintenance' especially and like you said general M car 'tax'. One can dream anyway. But more on the reality front - did read the whole 330i thread as well and was a great read too, both threads enlightening as I've never even driven one of these cars! I do recall 330i didn't seem to have the same amount of issues for almost the same car (turbos and related differences notwithstanding)...perhaps down to getting it earlier in it's life so looked after better than the 335i? Perhaps so as your 130i has been good and quite similar, so finding a car that's been looked after well is the especially-crucial-BMW-first-step.

-

Nice. Dont worry about the time of not running. My current skyline hasn't run since I bought it. About 8 years ago.

-

It's also worth noting that I am heavily and unconditionally biased. I've had a lot of cars including some GTRs a fair while ago. I love my BMW's now a lot. They make no sense a lot of the time and the guys on here remind me regularly that I could get something else that does what I want better and cheaper. If you're going to take on an older BMW it's definitely a commitment. If you bail on it early you'll lose money and also the ability for it to put a smile on your face. Stick with it and it just gets better. f**k I should get into advertising.

-

Recommended Posts

Create an account or sign in to comment

You need to be a member in order to leave a comment

Create an account

Sign up for a new account in our community. It's easy!

Register a new accountSign in

Already have an account? Sign in here.

Sign In Now